Our contact details

Poland / Global - Sergey

+48 884-623-735 - calls / whatsapp

Monday-Saturday: 9:00 - 19:00 (CET)

USA and Canada - Sergey

+1(201)409-44-90 - calls only

Monday-Saturday: 3am - 1pm (GMT-4)

Germany / Austria / Switzerland - Yuliya

+49(341)65-18-3141 - calls / whatsapp

Monday-Friday: 9:00 - 16:00 (CET)

email: office@logluxe.eu

31-236, Kraków, Poland

al. 29 Listopada 130, office 329

Feel free to ask questions and quotes via whatsapp.

Follow our Social Media via links below.

+48 884-623-735 - calls / whatsapp

Monday-Saturday: 9:00 - 19:00 (CET)

USA and Canada - Sergey

+1(201)409-44-90 - calls only

Monday-Saturday: 3am - 1pm (GMT-4)

Germany / Austria / Switzerland - Yuliya

+49(341)65-18-3141 - calls / whatsapp

Monday-Friday: 9:00 - 16:00 (CET)

email: office@logluxe.eu

31-236, Kraków, Poland

al. 29 Listopada 130, office 329

Feel free to ask questions and quotes via whatsapp.

Follow our Social Media via links below.

We use cookies to provide the best site experience.

What is exactly sold when buying a prefab home kit?

Explore full list of items you get once you order house kit from LogLuxe.

Explanation of symbols

✅ - supplied with shell kit

🔵 - can be ordered at an additional cost

❌ - not supplied, due to high transportation cost or design preference differences or construction specifics

*The exact contents of the kit may differ from the images shown, depending on the specifications or design of the house. The images are for illustrative purposes only and do not constitute a public offer.

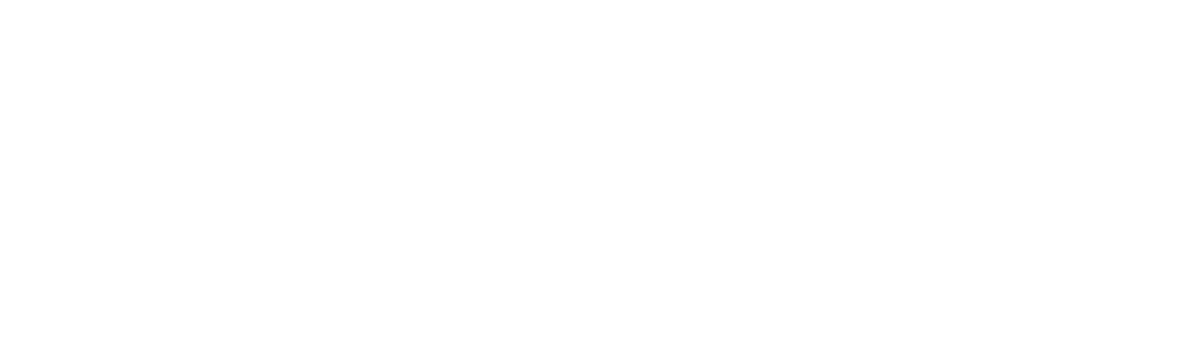

The Ridge

- Cover plate (on both sides) ✅

- Ridge vent 🔵

- Soft bitumen shingles (can be any other roof cover) 🔵

- Rough ceiling board ✅

- Alignment rail ✅

- Tie bolt ✅

- Ceiling lining ✅

- Rafter ✅

- Vapor barrier 🔵

- Insulation ❌

- Anti-condensation film (waterproofing)🔵

- Counter battens ✅

- Battens ✅

- OSB battens ✅

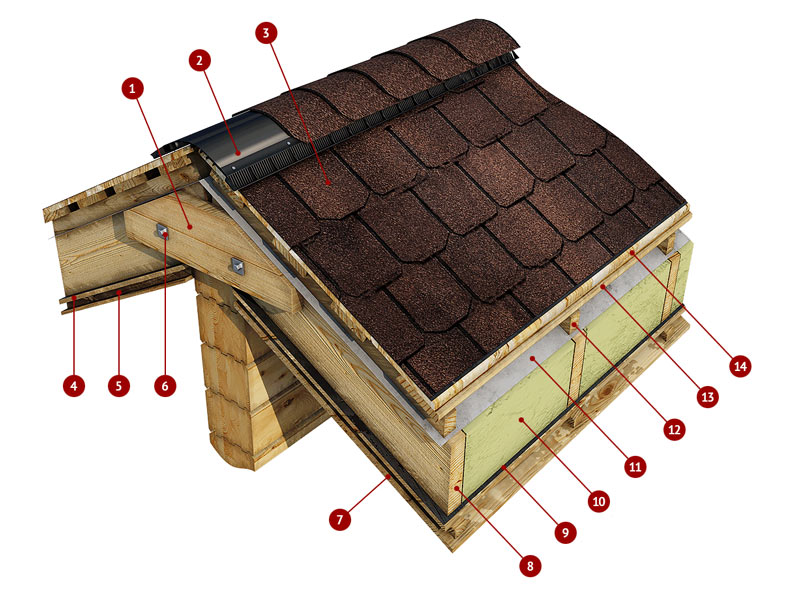

Gable and Roof

- Mosquito net ❌

- Anti-condensation film 🔵

- Battens ✅

- OSB battens ✅

- Soft bitumen roofing 🔵

- Eaves board ✅

- Eaves lining ✅

- Log wall ✅

- Sliding plate for rafters ✅

- Vapor barrier 🔵

- Rafter ✅

- Ceiling lining ✅

- Counter battens ✅

- Rough ceiling board ✅

- Alignment rail ✅

- Insulation ❌

Log to Foundation Joist

- Lag screw ✅

- Timber beam ✅

- Base plate ✅

- Waterproofing ✅

- Reinforced concrete foundation ❌

- Drip cap ❌

- Facing tiles (plinth finish) ❌

Terrace Deck Cross-Section

- Deck beam ✅

- Terrace board ✅

Balcony Cross Section

- Balcony floorboard ✅

- Floor battens ✅

- Waterproofing ✅

- Board ✅

- Wind protection ✅

- Ceiling sheathing ✅

- Сeiling rafter ✅

- Drip cap ❌

Window Installation (Sill)

- Casing block ✅

- Casing board ✅

- Window trim ✅

- Log wall ✅

- Windowsill board ✅

- Sealant ✅

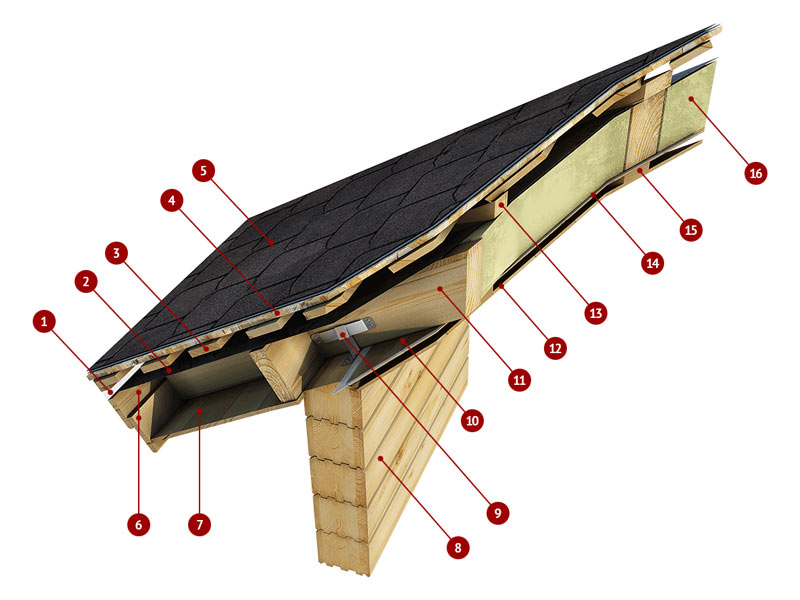

Window Installation

- Log wall ✅

- Casing block ✅

- Window trim ✅

- Casing board ✅

- Soft insulation ✅

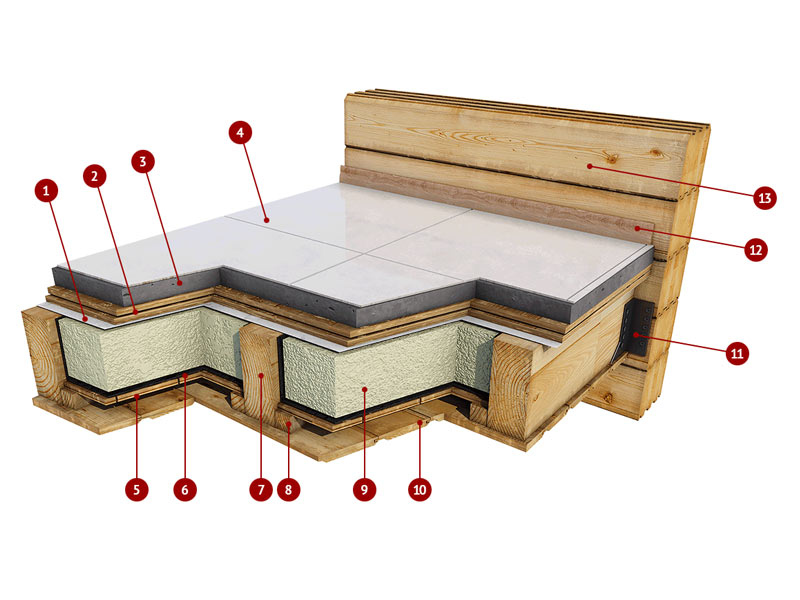

Floor Cross Section

- Vapor barrier 🔵

- Moisture-resistant plywood 🔵

- Screed (dry/wet, 50 mm + utilities) ❌

- Tile (10 mm) ❌

- Rough floorboard ✅

- Wind protection 🔵

- Floor joist ✅

- Ledger strip ✅

- Insulation ❌

- Foundation ❌

- Waterproofing ✅

- Embedding board ✅

- Skirting board 🔵

- Timber wall ✅

Floor Cross Section

- Vapor barrier 🔵

- Moisture-resistant plywood 🔵

- Screed (dry/wet, 50 mm + utilities) ❌

- Tile ❌

- Rough floorboard ✅

- Wind protection 🔵

- Сeiling rafter ✅

- Ledger strip ✅

- Insulation ❌

- Ceiling lining ✅

- Installation plate (bracket) ✅

- Skirting board 🔵

- Timber wall ✅

What's included in the basic offer?

What's included in the basic offer?

Basic offer only used to give you estamate price. It means you can add or remove anything from the package.

Every order content is discussed individually.

1) Blueprints and other documentation

7 7/8” (200 mm) thickness option - optimal solution for year-round living in the middle climatic zone, in terms of the ratio of cost and energy efficiency. 9,45” (246 mm) - is for the most frosty and windy regions, like north of Canada or Syberia.

Available Log Height - 7 3/32"; 10 5/8”; (185; 270 mm)

Price is normally given for 7 3/32" (185 mm) height option. Higher logs are used in bigger houses, where the larger size of the log correlates more with the scale of the building.

The U-value for the calculated beam wall is 0,585. It means, that 7 7/8” (200 mm) thick laminated timber wall is equivalent to an 31,5” (80 cm) brick wall)

Cutting of material according to the project design, with the cutting of the end grooves, with protective finishing of the ends, ready to paint. Sanitized and kiln-dried, pre-cut corner joinery system, pre-cut spline notches, pre-cut window and door openings (*minor trimming and odd-shaped openings may need to be cut on-site). Log wall erection diagrams included. Log bundles are well factory wrapped from six sides.

Internal walls are made in a framed design - to reduce the final cost and the possibility of various interior finishes. The use of beams for interior walls is an option, and is available at an additional cost. In this case internal finishing won’t be needed - which is lowering final cost and speeds up moving in.

- Preliminary architectural drawings (NOT STAMPED).

- Shop structural drawings (NOT STAMPED). If required by local building authorities, review by a state-licensed professional is to be done at additional cost.

- Easy to read Assembly Manual.

- Sill plate board (larch wood) to put under the walls and protect the wall beams from moisture - 2” х 7,9” (50x200 mm) - (for slab type foundation - highly recommended option)

- Strapping beam (with pile foundation) (at least 5.9”x5.9” (150х150 mm) - may be thicker depending on the project)

- Log wall system: first grade white pine (free of knots and wood defects, for increased durability of the beam) Stable engineered wood – GLT. interlocking profiled Logs with cups according to the house project.

- The logs are presented in 3 sizes in width and 2 in height - as illustrated in the gallery above.

7 7/8” (200 mm) thickness option - optimal solution for year-round living in the middle climatic zone, in terms of the ratio of cost and energy efficiency. 9,45” (246 mm) - is for the most frosty and windy regions, like north of Canada or Syberia.

Available Log Height - 7 3/32"; 10 5/8”; (185; 270 mm)

Price is normally given for 7 3/32" (185 mm) height option. Higher logs are used in bigger houses, where the larger size of the log correlates more with the scale of the building.

The U-value for the calculated beam wall is 0,585. It means, that 7 7/8” (200 mm) thick laminated timber wall is equivalent to an 31,5” (80 cm) brick wall)

Cutting of material according to the project design, with the cutting of the end grooves, with protective finishing of the ends, ready to paint. Sanitized and kiln-dried, pre-cut corner joinery system, pre-cut spline notches, pre-cut window and door openings (*minor trimming and odd-shaped openings may need to be cut on-site). Log wall erection diagrams included. Log bundles are well factory wrapped from six sides.

Internal walls are made in a framed design - to reduce the final cost and the possibility of various interior finishes. The use of beams for interior walls is an option, and is available at an additional cost. In this case internal finishing won’t be needed - which is lowering final cost and speeds up moving in.

- An intertwined seal for corner joints

- Laminated beams structural posts - 8” х 8” (200x200 mm) - where required by project.

- The casing frame for window and door installation is 1.6" x 2" (40x50 mm) dry planed block. It is installed inside the window opening, so that the shrinkage of the house after assembly does not change the size of the opening where the window is installed.

- Boards for extension jambs for installation of windows and doors, engineered wood 1,6" x 7,9" (40x200 mm)

- A set of supplies to assemble the wall set.

- Floor joists - planed wood (Glue Laminated Timber beams)

- Subfloor - sawn board 0,6" (15mm)

- Stopper bar - sawn block 1,6" x 1,2" (40x30 mm)

- Framing lumber for exterior decks (if required by the project)

- A set of supplies to assemble the wall set.

- Roof battens - sawn board 1" (25mm)

- Ventilation battens - sawn bar 1,7" x 2" (43x50 mm)

- Roof truss system - engineered wood (Glue Laminated Timber beams)

- Inner solid roof sheathing - sawn board 0,6"(15mm)

- Inner ventilation battens - sawn bar 1" x 2"(25x50mm)

- A set of supplies to assemble the wall set.

- Eaves soffit - planed board 0,8" x 4,7” (20х120 mm) - where applicable by project

- Fascia - planed board 0,8" x 4,7” (20х120 mm) - where applicable by project

- Casing board for windows and doors - planed engineered wood 0,8" x 4,7”(20х120 mm) (Glue Laminated Timber boards)

- Casing board for the ends of the walls (optional, at an additional cost)

- Framing lumber for terrace railings (optional)

- Terrace decking board, engineered

What's not included into the kit?

What's not included into the kit?

- This log house kit is made of high-quality northern white spruce, easy for professional assembly. You are buying only the prefabricated log kit. please read above what is included in the kit. No labor or any other materials are included! Average time for assembly of the kit by an experienced team of 2-3 workers is 30 - 45 days.

- This kit does not include windows, doors, plumbing, electrical, fixtures such as toilets sinks or cabinets.

- Foundation, wall erection, interior finishing, stairway, plumbing, hvac, electrical are to be paid by buyer separately to local suppliers. We are willing to provide free consulting to make your building experience as smooth as possible, however we can not provide you assembly service.

- Roof insulation and covering can be included into the kit at additional cost.

- All permits and related fees are the purchaser’s responsibility.

- the buyer is responsible to meet the building permits and requirements in their state/county. so please check at your county building department office to find out what is required. We are willing to provide free consulting to make your building experience as smooth as possible.

- Customers agree to hold LogLuxe and any authorized dealers free of any liability for improper installation, maintenance, and repair of any LogLuxe products.

- We will be glad to give you a free price quote on your custom house inquiry.

What can I order additionally?

What can I order additionally?

- Drilling holes for concealed wiring

- Metal tile roofing

- Mineral insulation

- It is possible to modify the package contents or use any size logs from the list. Quotes available upon request. Subject to price adjustment.

- Modifications to interior layout are possible.